Recent Commercial Posts

SERVPRO of Fenton/South Ballwin Commercial Restoration Services

5/25/2023 (Permalink)

SERVPRO of Fenton/South Ballwin helps with all your commercial restoration service needs.

SERVPRO of Fenton/South Ballwin helps with all your commercial restoration service needs.

SERVPRO of Fenton/South Ballwin offers many different services that we offer for commercial properties. We understand that it is difficult at times to schedule services during business hours, so we can work with you to find a time that best fits you and your company's needs.

If needed we can work in one section at a time in order to keep your business open while we work, or we can attempt to schedule it before or after business hours.

In addition to our emergency water, fire, and storm clean up services we also offer many other cleaning services. These include, but are not limited to:

- Air Ducts and HVAC

- Biohazard

- Carpet and Upholstery

- Ceilings, Floors, and Walls

- Drapes and Blinds

- Odor Removal

- Sewage

- Trauma and Crime Scene

- Vandalism

FIRE DAMAGE

The faster SERVPRO of Fenton/South Ballwin arrives on-site to perform fire, smoke, and soot cleanup and restoration, the better the results— including lower claim costs.

Within four hours of a loss notification (and usually much earlier), we will be on-site to help ensure a fire damage is handled properly by utilizing the following services:

Structural Cleaning

After a smoke or fire damage, ceilings, walls, woodwork, carpeting, and floors will often need a thorough cleaning. SERVPRO® will pretest to determine the extent of damage, then use the specific equipment and cleaning products required to clean and protect the different types of surfaces found within the structure.

Contents Cleaning

All the restorable contents in the affected areas will be professionally cleaned and deodorized. This includes area rugs, furniture, draperies, and upholstery. SERVPRO can provide wet or dry-cleaning services. Additionally, all other restorable contents will be cleaned and deodorized to preloss condition. This includes electronics, art, wood furniture, kitchen items, clothing, bedding, and much more. Finally, we can provide an inventory list of all “to be claimed” items.

Deodorization

We provide specialized services that rid your insured’s home or place of business of offensive odors left behind by fire or smoke damage. We do not merely cover up lingering odors with a fragrance; we seek out the sources of the odor and remove them.

WATER DAMAGE

If you have recently become a victim of commercial water damage, you may be wondering what you can do to mitigate your damages. There is a critical period in which certain actions must be taken to preserve as much of your property as possible and to decrease any health risks when water damage has occurred in a commercial space.

Preparing a Space for Water Damage Restoration

Before you enter your commercial space or any flooded building, you will need to make sure the electrical power to the structure is shut off. You should also be aware that during a flooding event, small animals or reptiles tend to seek shelter inside of buildings. Be prepared to deal with the discovery of wild animals in your space.

Protect yourself from entering any flooded building by wearing an organic vapor respirator. You can purchase these at any local paint and building supply stores. You also want to have rubber gloves, protective clothing, and eye protection. The first thing you should do is ventilate the affected areas by opening the windows and placing fans where possible.

Unfortunately, there likely will be items that you need to throw away. Any items that are porous and have absorbed contaminated floodwater cannot be restored. If your commercial space has drywall, mattresses, pillows, box springs, particle board, carpets or carpet pads, these will need to be discarded if they have become saturated. However, there is good news: If you have clothing or household fabrics that can be machine-washed, you may be able to salvage them. Use your washing machine to clean these items with a 10-minute soak at the minimum in hot water with detergent. The soap and normal wash should remove most of the contamination and any staining that is present.

Be aware that your commercial space will need a thorough professional inspection, cleaning and possibly restructuring. Water damaged walls and installations must be removed and repaired, and pockets of saturation should be exposed for drying and sanitizing. Always remember that mold growth could take a few days to appear as it thrives in a moist environment with organic-type materials such as paper or particle board and in temperatures that range between 60 and 86 degrees Fahrenheit. Keep good airflow throughout the interior environment, and maintain moderate temperatures to decrease the risk of any mold growth. It is also important that you let your space dry out before any rebuilding occurs.

If you would like more information on any of the services listed above, please call SERVPRO of West Kirkwood/Sunset Hills at (636) 527-5990.

Team of Over 1700 Franchises Nationwide

9/29/2020 (Permalink)

Commercial Water Damage in Fenton, MO

Commercial Water Damage in Fenton, MO

Size is not always an indicator of strength; but when you are a restoration company with the resources of over 1,700 franchises- size matters.

At SERVPRO of Fenton/South Ballwin we are equipped to handle a loss of any size. But the question always comes into play, what happens when there are multiple losses.

Typically, we see this scenario play out during natural disasters or major storms. The benefit that we have at SERVPRO of Fenton/South Ballwin is not only do we have the capacity to produce any size loss; but we can combine our strength with a large network of other SERVPROs nationwide that can provide assistance and extra equipment.

At SERVPRO of Fenton/South Ballwin not only do you get the local franchise, but you also get the strength of one of the nation’s largest restoration company. In the last few years, we have been fortunate to have the network of SERVPRO’s to provide us more equipment and PPE during nationwide shortages.

If you have experienced fire or water damage, we are always here to help! Call us 636-527-5990 so we can address your damages quickly.

Is your Fenton, MO Business protected by a working fire suppression system?

9/28/2020 (Permalink)

Is your Fenton, MO business protected by a working fire suppression system?

Is your Fenton, MO business protected by a working fire suppression system?

For commercial and residential buildings all around St. Louis, MO, having a working fire sprinkler system installed is the single most effective means of fighting fires. According to National Fire Protection Association (NFPA) statistics, damages to manufacturing facilities, stores, offices, and healthcare facilities with a working fire sprinkler system installed were 60% lower than damages to building with no fire sprinkler system! Make sure your building, employees, customers, assets, and valuables are safe and secure by installing a fire sprinkler system in your office or government building.

Since fire sprinkler systems need to be in working order at all times, they need to be inspected annually to ensure that they will operate properly during a fire emergency. During a fire sprinkler system test, physical checks are performed on all the parts of your fire sprinkler system. These checks include water flow tests, fire pump tests, alarm tests, and trip tests of dry pipe, deluge, and pre-action valves.

In addition to annual fire sprinkler system inspections, you must also carry out quarterly flow tests. Written records of all quarterly fire sprinkler system inspections must be maintained in accordance with NFPA 25.

If properly maintained and inspected, a fire sprinkler system can provide your Fenton, MO building with highly effective fire sprinkler services and fire protection for decades.

Here at SERVPRO of Fenton/South Ballwin, we are here to help 24/7/365 for all your restoration needs!

EPA Compliance Advisory on Product Claims

6/16/2020 (Permalink)

The U.S. EPA recently issued a Compliance Advisory titled “What You Need to Know Regarding Products Making Claims to Kill the Coronavirus Causing COVID-19”. A copy of the Compliance Advisory is included in the attachments on this page. Per the EPA:

The purpose of the Compliance Advisory is to address concerns related to products being used to disinfect surfaces which include claims to kill and/or be effective against SARS-CoV-2, the

coronavirus causing the disease COVID-19. For some of these products, those claims have not been reviewed or accepted by EPA and, therefore, may present a risk to consumers, and healthcare

providers in particular.

The EPA uses the following very strong language that is helpful in advising our clients and

customers regarding the increasing number of new age products and methods that are being pitched with dubious efficacy and other claims in connection with COVID-19, and challenging the use of those questionable products and methods in the marketplace:

It is unlawful for any person to distribute or sell a pesticide in the United States making claims

to that it will kill a particular pathogen, unless that pesticide is registered with EPA and that

particular claim has been deemed acceptable by the agency. EPA is receiving a steady stream of

tips/complaints concerning potentially false or misleading claims, including efficacy claims,

associated with pesticides and devices. These tips/complaints are being actively reviewed and

efforts are being made to identify potentially violative products. EPA intends to pursue

enforcement against products making false and misleading claims regarding coronavirus. EPA is

working with e-commerce platforms to remove/prohibit these fraudulent and/or otherwise inefficacious products from the marketplace. EPA is also coordinating with the U.S. Department of Justice and other federal partners to bring the full force of the law against those selling or otherwise distributing violative products.

SERVPRO of Fenton/South Ballwin consistently uses only SERVPRO approved cleaning and disinfecting products and methodologies to help combat the COVID-19 crisis. We are always there to help! 636-527-5990

Certified: SERVPRO Cleaned program

5/26/2020 (Permalink)

Let us help you get back to business

As our communities re-open, we are all moving back toward a new kind of normal. The expectations of visitors, customers, and employees who come into our establishments have evolved, and staying safe and well is a top concern. The global COVID-19 pandemic has changed what it means to be clean, and we have developed a program to help your business meet the new higher standard of clean that is now expected.

Certified: SERVPRO Cleaned is a defensive cleaning program we are offering to businesses and commercial locations to address the current COVID-19 pandemic. This proactive viral pathogen cleaning program goes well beyond janitorial or carpet cleaning. By choosing Certified: SERVPRO Cleaned, you, your employees, your customers, and your community can rest assured that you have selected a higher cleaning standard – you are Certified: SERVPRO Cleaned.

Extensive training and specialized products

As the #1 choice in cleanup and restoration*, we stand on more than 50 years of experience and expertise to help your business become Certified: SERVPRO Cleaned. Beyond fire & water, SERVPRO professionals are trained and experienced in biohazard decontamination and chemical spills – always adhering to the cleaning and decontamination standards set by the Centers for Disease Control and Prevention and local authorities.

From formulating and creating our proprietary cleaning products, like SERVPROXIDE, at our headquarters in Gallatin, TN, to taking the utmost care while disinfecting, we will ensure you and your business are set up to inspire consumer confidence as the economy continues to reopen.

3 C’s – Consult, Clean, and Certify

When the stakes are this high, you want a partner who has developed an industry leading, proprietary training program, cleaning solutions, and remediation processes over decades. We have cleaned up some of the most challenging biohazards imaginable. Certified: SERVPRO Cleaned reflects our unique experiences and capabilities. The program is grounded with our unique 3 C’s: Consult, Clean, and Certify.

- Consult – Every business is different, which is why you will be assigned a Cleaning Protocol Consultant who understands your business and will create a cleaning program to meet your specific needs. This program will be developed based on your business type, size of space, amount of high frequency touchpoints, foot traffic and congestion points.

- Clean – Based on your specific business needs, your location will undergo a thorough, deep clean, using exclusive cleaning products, according to protocols set forth by the CDC. Our employees have years of experience, and we will go beyond the scope of work that regular janitorial staff perform. Cleanup procedures generally include cleaning of porous and non-porous surfaces, disinfecting of non-porous surfaces, cleaning and disinfecting of equipment, tools, and/or supplies used for cleanup process, and disposal of hazardous materials. In the event of a suspected or confirmed COVID-19 event, we will be there cleaning within 24 hours to ensure you get back to business as quickly as possible.

- Certify - Once your business location has been Certified: SERVPRO Cleaned, you will gain access to proprietary signage, digital emblems, and other collateral that communicates that you’ve selected a higher standard of clean available to help protect your employees and customers. And because we add the day, month, and year to that proprietary stamp of clean, your guests will know that not only did you choose Certified: SERVPRO Cleaned, but that your location is being cleaned regularly at this standard.We are Here to Help – 24 hours a day, seven days a week – until life is back to normal in the communities, we all call home.

- Call SERVPRO of Fenton/South Ballwin today at 636-527-5990 for your Certified: SERVPRO Cleaned consultation.

- Call today for a Certified: SERVPRO Cleaned consultation

Emergency Ready Profile (ERP)

4/16/2020 (Permalink)

SERVPRO offers a lifeline to all businesses, The Emergency Ready Profile (ERP). ERPs are a profile set up by SERVPRO Professionals to aid in putting a halt to business interruption, and to get businesses back in working order quickly. The Emergency Ready Profile is presented to the businesses’ responsible party in a paper copy form. The profile is put together in a folder with all the pertinent information in one place, ready to use in a moment’s notice. The ERP contains vital information to the business, as well as the SERVPRO Franchise. It is set up with a property overview, building access details, utility contacts and shut off locations, emergency/key contacts and a multitude of pictures and notes. Another reason ERPs are so great is because a SERVPRO Professional will put the profile together for your business free of charge. Contact your local SERVPRO Franchise and have them come out to set up an Emergency Ready Profile for your commercial property. It will alleviate the stress of a prolonged business stoppage and get your business up and running before you know it. Call SERVPRO of Fenton/South Ballwin (636)527-5990 for all you restoration needs.

Removing Moisture from Materials

9/9/2019 (Permalink)

The rate at which moisture moves through materials depends upon two primary factors: the type of material affected and the degree of wetness. The type of material affected will vary in permeability (ability for water to pass through the material), hygroscopicity (ability to absorb water), thickness, density, temperature and "R" factor (resistance to heat transfer).

Each of these characteristics will influence the way in which water travel through the material. The degree of wetness will influence the moisture movement, in combination with other material characteristics, by indicating the type of water being addressed. Water will be present in one, two or three forms:

- Surface Water

- Free Water

- Bound Water

Surface water is readily available at the surface of a material. It is liquid, visible and will evaporate readily. All materials are capable of supporting surface water. Surface water is best removed physically using mechanical extraction equipment or other physical means. Minute amounts of remaining surface water are readily evaporated using large amounts of airflow and moderate temperature and humidity.

Free water is present within a material but is not bonded. It exists in cavities, open pores and other air spaces within the material. It is liquid, generally visible by a darkening of the material (e.g., wood) and can evaporate readily. Most materials are capable of supporting (containing) free water. Materials not capable of retaining measurable amounts of free water are non-permeable, non-porous materials such as vinyl, vinyl composite, steel, rubber and some other solid, synthetic materials.

Bound water is absorbed by the material and held captive by chemical bonds. It is similar to vapor in that it is not fluid, yet similar to a solid/liquid in that it is bonded to other molecules. Because it is bound to other molecules, it must first be freed before it can be removed.

Two Drying Methods

8/19/2019 (Permalink)

After making the decision of whether or not to dry a material, Project managers begin evaluating how to begin the restoration work. Many methods are available - each applying a different combination of humidity control, temperature, airflow and physical manipulation of the material (e.g., injection of airflow, perforation, removing finish materials).

Our Project Managers use the information obtained during evaluation of materials to help select the best drying method for the job. Generally there are two primary methods to promote drying of affected structures: 1) disruptive methods and 2) aggressive methods.

Disruptive Drying Methods

Disruptive drying methods involve removing wet items, injecting air to speed drying, or perforating surfaces to allow water to evaporate. The term disruptive is used because repairs will have to be done after the structure has been dried. Use disruptive methods when contamination, damage, cost or customer concerns require removal or manipulation of the affected material.

Aggressive Drying Methods

Aggressive or "in-place" drying methods involve leaving wet items in the structure and drying them in-place using warm, dry direct airflow. Aggressive methods are used when contamination and damage are not concerns, and when it is cost effective to dry an item instead of replacing it.

Project Managers will use aggressive drying methods when all of the following are true:

- The water intrusion came from a sanitary source (Category 1).

- Drying carpet and underlay (pad, cushion) in place will not cause structural damage to subfloor (especially hardwood).

- Adequate dehumidification is available and usable on site.

- Deep extraction tools are available.

The success of each decision made during the restorative drying process depends on the information upon which the decision was based. A skilled technician with quality meters will make the proper decision at each phase of the project.

Installation of Air Movers

5/20/2019 (Permalink)

Air movers specifically distributed to ensure proper distribution of air.

Air movers specifically distributed to ensure proper distribution of air.

Air movers are placed in the environment to ensure rapid evaporation across all affected surfaces. The number of air movers necessary depends upon the number of wet surfaces, the amount of water present, and the ability for air to reach each wet material (e.g., wall cavities, behind cabinets, and under contents).

The IICRC S500 Standard recommends that air mover installation quantities should be based on the amount of wet surface area in affected spaces. For the initial phases of drying, air movers should produce continuous airflow across affected material surfaces. A step-by-step process for determining the proper number of air movers is:

- Place one air mover for each affected area.

- Add one air mover for every 50 to 70 sqft. of affected floor area.

- Add one air mover for every 100 to 150 sqft. of affected wall surfaces (above 2') and ceiling surfaces.

- Add one air mover for every room offset or inset greater than 18 inches.

This calculation should provide an appropriate amount of air movement for most water intrusions, but can vary depending of the situation and type of materials affected.

Once the number of air movers to be installed has been determined, several factors will influence their actual placement. These factors include: the type of material affected, the degree of saturation, the accessibility of the actual wet surface, power availability and equipment availability. Below are some general guidelines for installation of air movers:

- Air movers are directed toward the wall at a 5 to 45 degree angle, depending on the type of air mover.

- The air mover's snout will almost touch the wall, within in 1 to 2 inches.

- All air movers in each area will face the same direction to ensure that air movers are not pushing against each other.

- When placing air movers, we need to consider the need for circulation throughout the affected area.

- Specialty air movers may be necessary if building cavities require air flow.

Essential Elements for In-Place Drying

4/2/2019 (Permalink)

High value structural materials and contents that have slight reversible damage are dried aggressively. This procedure is referred to as drying in place. Drying in place means that the wet surfaces are dried with little or no manipulation.

Deep extraction tools combine three important elements that contribute to effective water removal: speed control, a vacuum seal and weighted compression.

- Mechanical speed control is essential for a consistent extraction over the entire carpeted surface.

- A reliable vacuum seal is essential to ensure air flows through the pad and carpet to remove water.

- Weighted compression is needed to force the air to move deeply through the pad and remove the stubborn water the light wand would leave behind.

Thorough extraction requires these elements. Without them, highly porous materials like carpet and pad cannot be dried in place. Too much water is help within these materials to rely on evaporation alone to restore them.

Desiccant Dehumidifiers

3/28/2019 (Permalink)

Desiccant Dehumidifier used for Commercial Water Damage

Desiccant Dehumidifier used for Commercial Water Damage

Desiccant Dehumidifiers utilize chemical attraction instead of condensation to remove water from the air. Because they do not use condensation, they are not limited by low dew point temperatures, and when used properly, they produce the lowest vapor pressure of any dehumidifier. Portable desiccant dehumidifiers work best in cool and/or dry environments. The cooler and drier the air going into the desiccant, the drier the air will be coming out.

Desiccants are commonly used to dry dense materials (hardwood floors and plaster walls) due to the large vapor pressure differentials they can create between the surface and the air, Desiccants excel at large loss drying, because they can be made in virtually any size.

Desiccants do not collect water in a pan for automatic pump-out. Instead, they produce damp reactivation air, which must be vented outside the structure using temporary ducting. This venting often results in a pressure differential in the drying environment. The dry "processed air" is ducted into the affected area.

Desiccant dehumidifiers range in size and configuration dramatically. Desiccants used in restorative drying can be as small as a roll-on suitcase or as large as two semi tractor-trailers. Large desiccants are often self-contained dehumidification systems, utilizing onboard generators and running on propane or diesel fuel. When large catastrophic events occur, such as hurricanes or flooding, large desiccants can provide a means of dehumidification when little or no power is available.

How to effectively utilize Drying Chambers

3/28/2019 (Permalink)

Drying Chamber being set up by containing the affected area.

Drying Chamber being set up by containing the affected area.

One way to gain efficiency in a drying environment is to set up a drying chamber. A drying chamber is defined as the area in which the Project Manager will manipulate and control temperature, humidity and air flow to promote evaporation. Drying Chambers can be set up in a number of ways, including:

- Closing doors

- Taping up plastic sheeting

- Erecting semi-permanent barriers with plastic sheeting (Containment)

Inside the drying chamber is the best location for basic wet (salvageable) furnishing and contents. They will dry along with the structure.

Drying chambers can be very effective for large losses. If only a portion of the building is affected, we can contain the affected area to help speed up the drying process. Drying chambers can be an effective procedure for containing the potential spread of contaminants. Isolate contaminated materials by erecting containment barriers. Containment is even more effective when negative air pressure in maintained in the contaminated area. Negative air pressure is produced by exhausting air from the area with an air filtration device (AFD) while using barriers to restrict incoming air.

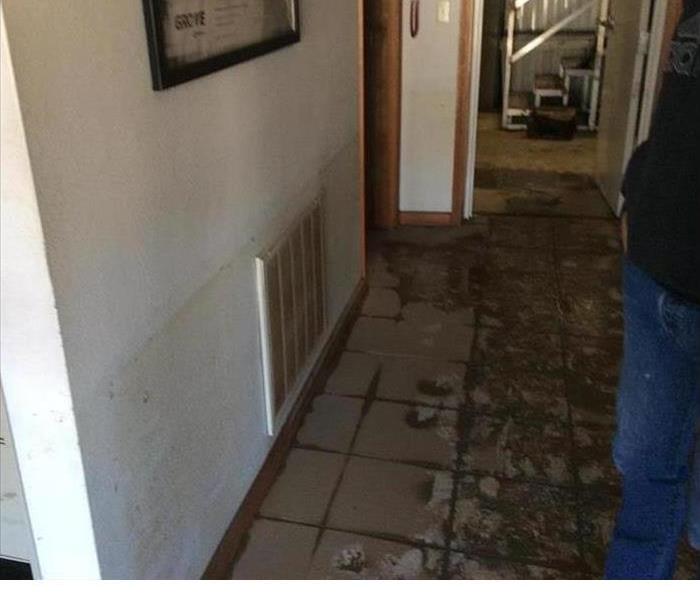

Flooded Commercial Business in Fenton, Mo

9/13/2018 (Permalink)

This flooded Business in Fenton, MO was the result of a near by lake flooding. The business office was flooded with muddy water causing not just water but mud to get everywhere. Our crews extracted the water throughout the commercial building. After the rest of the water was extracted the crews then tore up the tile flooring and took down the walls that were affected by the floor damage. The whole clean up process took three weeks. Three weeks may seem like a long time but with the amount of space that was damaged our crews kicked butt and got everything back "Like it never even happened." sooner than the business owner thought. The owner of the building was very pleased with how fast our crews worked and how great everything looked at the end.

Coping with flooding in your Fenton, Mo Basement

8/20/2018 (Permalink)

Have you recently suffered a long rain or maybe heavy storms in your area? Understandably, you may feel some apprehension before opening the door to your home's basement in Fenton, MO if you anticipate seeing water covering the floor. While your first instinct may be to grab your wet/dry vac, unfortunately there’s more involved in conducting a successful water cleanup in a basement flood.

How Does Water Get Into the Basement?

There is no one answer to how flooding occurs, but here are some common areas where water finds its way in:

• Window joints

• Cracks in the foundation

• The joint between the foundation footing and the wall

• Water heater or washing machine leaks

• Other joints in the walls, floor, and mortar

• Gutter cracks

• The floor drain

• The sump pump

• Burst sewer pipes

When Should You Call the Professionals?

If you have suffered basement flooding, your best bet is to call restoration specialists who are trained in removing the water and fully drying the area. Their expertise and high-end equipment can restore the room to its original condition. They can also test for hidden water damage lurking behind walls, which can often lead to the development of black mold.

What Is the Restoration Process?

Prior to beginning the restoration process, the specialist must determine any and all points where the water has entered the basement. Repairing the sources of the water prevents additional water from coming in and often includes sealing cracks, joints, and hose or pipe repair.

Professional machine extraction and dehumidifiers remove moisture from the air and the furniture, floors and assorted other materials. Carpet and padding often needs to be removed, and the professionals will determine how much of the baseboards, insulation and sheetrock require removal. After cleaning and sanitizing the affected area, the drying process begins and often requires upwards of three days to complete.

Flooding may seem disastrous, but you can get your basement back. The professionals will work alongside your insurance company to formulate a plan for basement reconstruction and restore your home back to normal. Visit http://www.SERVPROfentonsouthballwin.com for more information on commercial water damage or water damage in a residence.

Smoke Dectors Save Lives

7/10/2018 (Permalink)

Three of every five home fire deaths resulted from fires in homes with no smoke alarms or no working smoke alarms. To lower these rates make sure you replace all of your smoke detectors every 10 years. Here are of couple of things you can do to prevent fires in your Fenton/South Ballwin home or or business!

- Make sure all of your smoke detectors are interconnected. When one sounds, they all sound.

- All of your smoke detectors should be tested once a month.

- Larger homes or businesses will acquire extra smoke detectors.

Your Fenton/South Ballwin home or business is where we are at the greatest risk and where we

must take the most precautions. Most deaths occur from inhaling smoke or poisonous

gases, not from the flames. SERVPRO of Fenton and South Ballwin are here help if your home or business has a had fire due to faulty smoke detectors. Give us a call at 636-527-5990 and we'll make everything "Like it never even happened."

Flood or water Damage in your Fenton or Ballwin home?

5/4/2017 (Permalink)

Every flood or water damage event is a little different and requires a unique solution, but the general process stays the same. The next 6 steps will inform you exact steps SERVPRO uses for flood or water damage.

Step 1 - Emergency Contact

The restoration process begins when you call us. Our representative will guide you through the crisis and may ask several questions to help us better understand the equipment and resources.

Step 2 - Inspection and Water Damage Assessment

We determine the scope of your water damage at this stage. We inspect and test to determine the extent of damage and how far the moisture has traveled to ensure proper and complete restoration.

Step 3 - Water Removal / Water Extraction

The water removal process begins almost immediately and removes the majority of the water. We use powerful pumps and vacuum units to quickly remove hundreds or thousands of gallons from your property, which helps prevent secondary water damage and mold growth.

Step 4 - Drying and Dehumidification

We use specialized equipment to remove the remaining water that is harder to access. Our Professionals will use room measurements, temperature, and relative humidity to determine the optimal number of air movers and dehumidifiers needed to dry your home or business.

Step 5 - Cleaning and Sanitizing

We clean all of the restorable items and structures damaged by the water. We are adept at cleaning contents using a number of techniques. Our professionals are trained to provide sanitizing treatments and to remove odors and deodorize your property.

Step 6 - Restoration

Restoration is the process of restoring your home or business to its pre-water damage condition. Restoration may involve minor repairs, such as replacing drywall and installing new carpet, or may entail major repairs, such as the reconstruction of various areas or rooms in a home or business.

All of these steps help SERVPRO of Fenton and South Ballwin restore your home or business after flood damage occurs. Give us a call at (636) 527-5990 and well make your property "Like it never even happened."

Restring Your Commercial Property After A Water Damage

4/24/2017 (Permalink)

Flooding and water damage events in commercial properties are often complex with numerous issues that require a knowledgeable and flexible response. Whether we’re dealing with a relatively small water cleanup scenario or a large scale event, SERVPRO of Fenton and South Ballwin will work as quickly as possible to assess each unique situation and isolate the damaged area. In many instances, normal operations can continue in a temporary space while we restore your facility.

Restoring Commercial Properties Presents Unique Challenges

Our professionals here at SERVPRO are trained to be mindful of legal and environmental concerns and strive to fully restore the damaged area while working within your budgetary constraints. We understand that every hour spent cleaning up is an hour of lost revenue and productivity. So when an emergency situation arises in your Fenton or South Ballwin business, give us a call at 636-527-5990 and we’ll be there fast with the help you need!

We Can Help Your Business

4/13/2017 (Permalink)

SERVPRO is not just a name, it is a promise. A promise to make it "Like it never even happened." We understand that your emotions can be all over the place, and you have a right to feel confused and frustrated, no matter if it is your home or business because you want the job done NOW. We also understand when it is your business there needs to be a hustle to get the job done and done right, for you to open back up as soon as possible, because when you're close, you are not making money. We will work our hardest in restoring your business so you can feel "Like it never even happened" because that is the SERVPRO promise we make when we take your job. So if your Fenton or South Ballwin home or business is in need of us, give us a call at 636-527-5990

24/7 Emergency Service

24/7 Emergency Service